Introduction

Earned value management (EVM) is a Project management methodology that integrates schedule, costs, and scope to measure project performance. Based on planned and actual values, EVM predicts the future and enables PMs to adjust accordingly. EVM concepts were initiated over fifty years ago by the United States Department of Defense (DoD) to support their control processes with large defense acquisition programs. In 1965, the U.S. Air Force defined the criteria for their acquisition projects which included the basic concepts of EVM. Initially EVM was viewed as excessive overhead but became acceptable in the decades that followed. In 1987, PMI included an overview of EVM in their PMBOK Guide and in subsequent editions and during the 1990’s governmental procurement groups streamlined their activities to include EVM reform.

In 2023, Project Management Solutions published a white paper on Project Management Skills for Value Delivery after surveying hundreds of organizations of varied sizes and types that showed that PMs (includes PMPs) across the board were particularly unskilled at measuring work performed using earned value analysis. This red flag is unfortunate news, especially when we have computers that excel in doing this analysis!

Testimony now shows that EVM provides one of the most efficient and meaningful tools available to measure and report project cost, schedule, and performance. When EVM is applied properly and consistently, it takes the guesswork out of estimating project progress and performance. So, let us review the basic principles of EVM.

Basic Principles

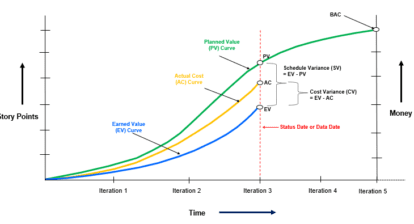

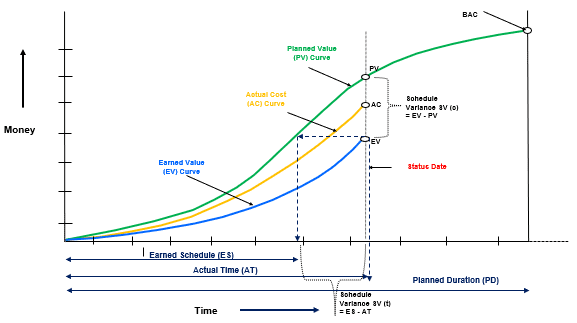

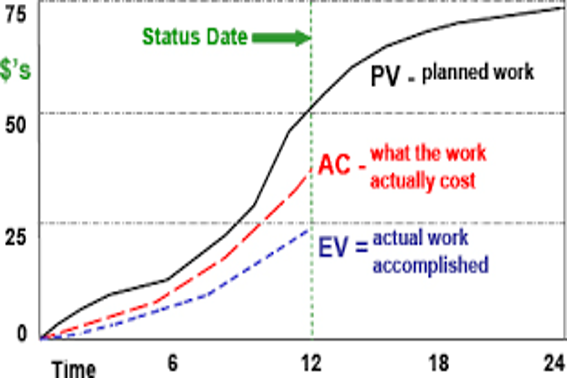

The underlining concept of EVM implementation is having a complete work breakdown structure (WBS) that defines the set of project deliverables and related work units that collectively represent 100% of the scope of work. In EV terminology the WBS boxes represent the Planned Value (PV) for that work unit and this value will be used for comparative purposes. In the schedule, the baselined WBS work units become distinct measures for evaluating periodic progress. PV is also known as budgeted cost of work scheduled (BCWS).

As the project advances, work unit planned performance through time is calculated against actual work completed to yield EV. It is the relationship between the budget and the percentage of completion of a project or EV = (% Completed) x Task Budget. EV is also known as budgeted cost of work performed (BCWP) which helps PMs measure a project’s performance.

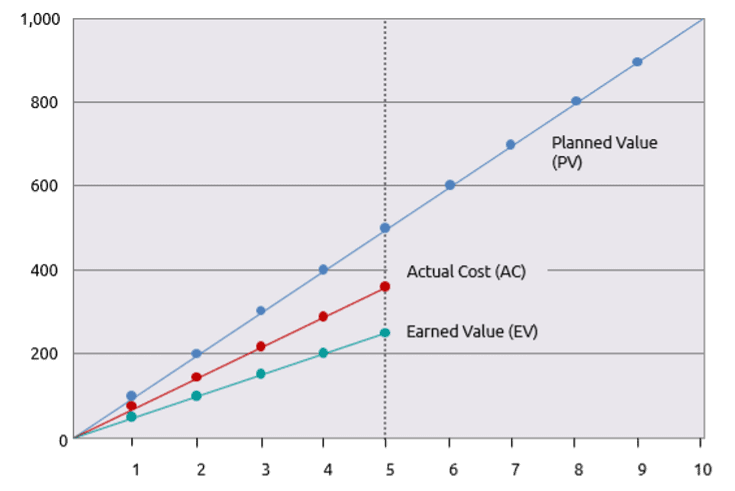

Actual Cost (AC) for the work unit is then used to provide both cost and schedule measures for that status point. AC is also known as actual cost of work performed (ACWP). See Figure 1 that shows a project’s progress status time for point 5.

PV = $500

AC = $375

EV = $250

Figure 1 – EV Progress Tracking

Cost Variance (CV) = EV – AC = 250 – 375 = -125

Schedule Variance (SV) = EV – PV = 250 – 500 = -250

As you can see the project is not going well with its negative variances and is in serious trouble. It has accomplished about 70% (250/375) of its budget. Said another way, it is running about 30% higher than budget for the work produced. From the schedule view, it shows the project is behind about 50% (250/500) of planned “speed” which means the project is about 50% behind schedule.

Microsoft Project

There are many ways to keep reining on your project’s EV within MSP.

- Go to View tab, Tables, More Tables and select your EV table: Earned Value, Earned Value Cost Indicators or Earned Value Schedule Indicators. When done, click Apply.

- Go to Report tab, Costs and select Earned Value Report.

- Go to Report tab, Visual Reports Export and select Excel’s Earned Value Over Time Report. When done, click View.

Summary

EV is a key performance indicator (KPI) that signifies a quantified value of work accomplished on a project at a given date and the main benefits of measuring this KPI are:

- Allows you to act quickly to identify early on in your project life cycle the differences between actual cost, planned costs and EV.

- Improves productivity and communication which the PM gains greater control over the project’s activities making it easier and faster to achieve project objectives and sticking to the timeline. It also improves communications with the stakeholders because it gives a clearer picture of all the activities involved in the project’s completion.

- Allows you to take a step back and look at the big picture which helps you to take the right steps moving forward to getting your project back on track.

A good article to read on this topic is from MPUG’s Elizabeth Harrin – Why EVM is Important – which inspired me to write this article. Your thoughts in the comment section below are welcomed.