An idea without a plan is nothing but a dream. You may be in a situation where you want to roll out a new strategy for your company or organization but are uncertain about where to begin. To make your ideas a reality, you must first organize them and devise a plan.

A process map allows you to optimize the entire workflow from top to bottom. It is how businesses scale their operations to meet deadlines. Setting up processes quickly follows the establishment of a business or a new team within a company.

Even in well-established companies with a workforce that is well-versed in internal processes, documentation of the workflows is required to ensure compliance, train new employees, and identify opportunities for improvement. That is why, whether a company is new or established, process mapping is beneficial.

Explore how process mapping can help your organization. Our guide on process mapping will help you learn how process mapping works (with examples), the benefits of process mapping, and how to create a process map to improve your team’s project planning and communication.

If you want to know why some of your projects are failing, achieve customer satisfaction, or plan a strategic vision, process mapping is the step to begin.

What is Process Mapping?

Process mapping is a visual strategy used to better understand how a process will work. It usually includes a diagram that depicts the workflow or all of the stages in a business process.

The goal of process mapping, which uses a workflow diagram, is to gain a deeper understanding of how a process or set of processes relate and operate effectively. By mapping your processes, you can come to know the following:

- Characterize what a company does.

- Acknowledge who is in charge of what is in the process.

- Determine the beginning and endpoints of a process (the output or final result of a process)

- Classify the aspects that contribute to (or prevent) the success of a process.

Business process mapping also enables you to select a particular objective and way of measuring, tracking and comparing it to your business’s ultimate aim. This includes determining whether a specific process is in line with the company’s overall objectives and functionality.

Although process mapping can be used to visualize any type of process, it is most frequently used for process analysis, training, integration, and continuous improvements. They are useful for communicating a complex process, addressing a recurring issue within a given process, or coordinating the responsibilities of multiple team members.

Significance of Process Mapping for Business Achievement

Process mapping allows you to quickly comprehend how processes work, how they can be enhanced or constricted, and how many steps are required to complete the process. Any business process can benefit from mapping.

If you specifically want to know about business process improvement, check this out:

Business Process Improvement: What it is and How to Implement it?

For procedural tasks, some organizations use process maps, which are similar to workflow diagrams, so employees know which measures to take in a process workflow. Process mapping is typically used to define company execution standards or procedures.

Since you are already reading about process mapping, we are speculating you are aware of at least a few advantages. However, read this section thoroughly because it will assist in reassuring those around you!

Since you are already reading about process mapping, we are speculating you are aware of at least a few advantages. However, read this section thoroughly because it will assist in reassuring those around you!

- It makes it easier for team members, stakeholders, or customers to effectively communicate about the process

- It is beneficial for scenario testing and what-if contexts.

- Can be used as a marketing tool to demonstrate to investors or industrial customers the dependability of your organizational processes.

- Is required for many types of standards and certifications, such as ISO 9000.

- Improves the readability of process documentation

- Increase understanding of the roles and responsibilities of those involved.

- Helps identify flaws in the process and where improvements should be made and aids teams in brainstorming ideas for improvement or new changes that will help tackle challenges such as employee retention, declining revenue, and so on.

- Helps in the reduction of costs associated with the development of products and services

- Facilitates the reduction of costs affiliated with the innovation process

- Strengthen teamwork and employee satisfaction

- Can be used to train the employees as learning material.

- Assists in improving the efficiency of work processes

When do You Need to Generate Process Map

If increasing effectiveness is your obvious priority, it may be time to create a process map to get a big-picture view of your process before diving into more detailed advancements.

While hiring consultants to evaluate your processes may be advantageous, this can also be accomplished in-house using a low-code workflow builder.

A process map is required in the following situations, in addition to efficiency:

- When more specifications about a process are needed

- When teams must generate process improvement ideas

- When a group strives to enhance connectivity,

- When process documentation is lacking

- When teams must detect faults leading to delays, uncertainty, or rework.

Process Mapping Examples

You can start creating process documentation in a variety of ways to design a process. You can use flowcharts, diagrams, mind maps, or whatever your imagination comes up with, but there are some widely used and recognized methodologies available.

The following is a list of various types of process maps, along with a brief description of when each can be used. Choose the right type of process map for your key targets.

1. Basic Flowcharts

A basic flowchart is a simple map that depicts the steps of a process as well as its inputs and outputs. A flowchart can be as simple as a visual representation of process steps or as complex as a deployment or top-down flowchart.

When to apply:

- To devise new projects

- To create and document a process for problem-solving

- To assist teams in better-communicating ideas

- Workflow analysis and management

Drawing Instructions:

Here’s a simple flowchart picture to help you learn how to make them.

If you want to be more specific about Flow chart mapping, try out one of these

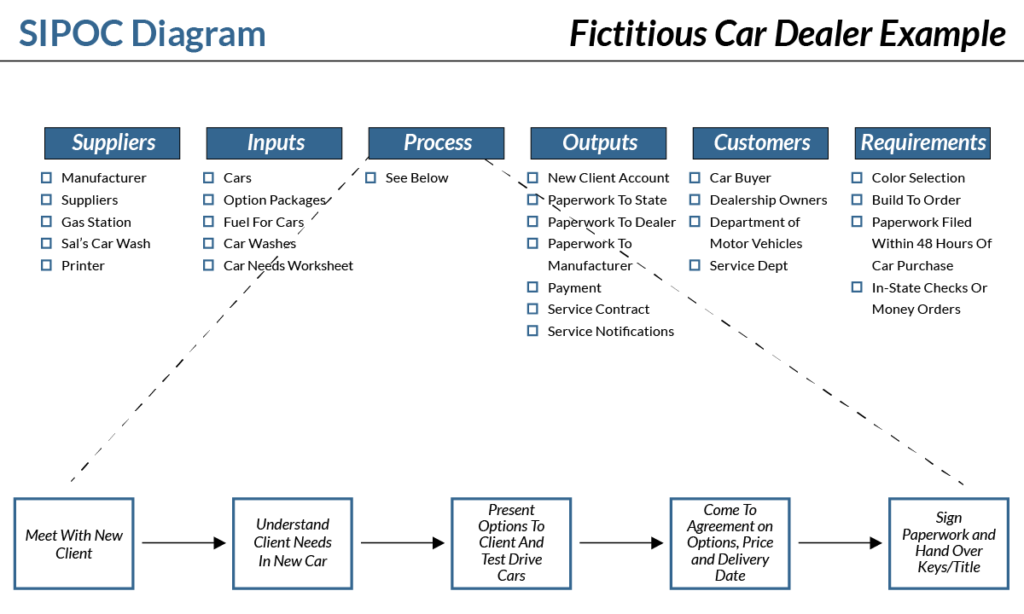

2. SIPOC

A SIPOC diagram is a high-level process map that results in a detailed diagram. Although it appears difficult at first, it is one of the most intuitive and practical methods for quickly understanding phases of a process when things begin and end with inputs and outputs.

When to use:

- Identify the key elements of a process before creating a detailed map

- To define the scope of complex processes.

- In the measure stages of DMAIC methodology

How to draw?

To create and grasp a SIPOC diagram, use the following prompts throughout each phase to better understand the flow’s purpose:

- Supplier: who enters the data to begin the process?

- Input: What does this person put in?

- Process: What are you going to do with this information?

- Output: What is the outcome of the processing?

- Customer: To whom did you deliver the processed data? Check the SIPOC diagram with the project manager and other stakeholders.

The framework for a SIPOC diagram when implemented, is shown below:

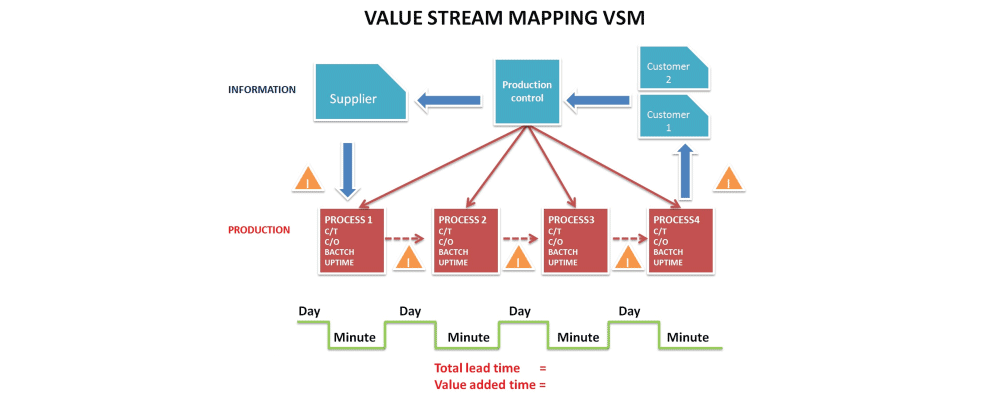

3. Diagram of Value Stream Mapping (VSM)

A Value Stream Mapping (VSM) diagram is one of the seven Lean principles, which is a methodology for continuously improving business processes by mapping a business process’s value. It is a visual representation of all customer interactions and the value they provide.

When to apply:

- To document, analyze, and improve the flow of information and materials

- To record metrics of process step inputs and outputs

- To acquire insight into decision-making and process flow

- To determine where future projects or subprojects should be focused

How to Draw?

A value stream map integrates all of these steps, provides a big-picture visualization of all added value or wasteful practices, and enables you to analyze and identify ways to improve the value delivery process.

A VSM appears as follows:

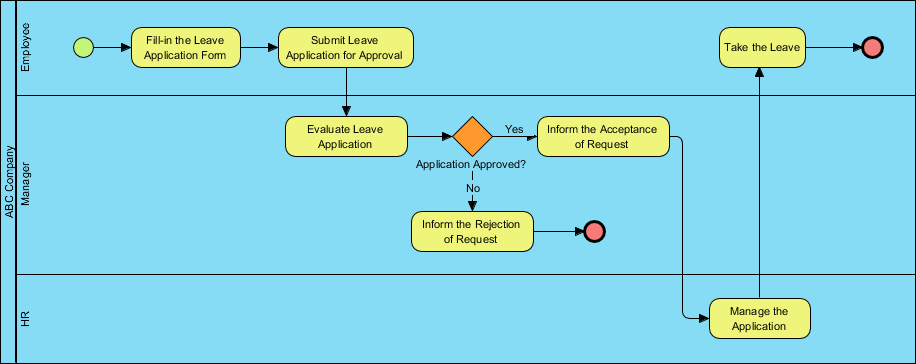

4. BPNM Diagram

BPMN is the most widely used process mapping methodology, and it employs flowchart symbols to create a graphic representation of the process, such as ovals for the start and endpoint, rectangles for tasks/steps, diamonds for decision points, and arrows to indicate the process flow direction.

When to Use

- It can be used to understand your As-Is state, A To-Be model can be created as the project progresses.

- Early models will most likely be high-level representations of the process.

- BPMN is used when it is critical to understand the steps required to complete a task, the order in which those steps must be completed, and who is responsible for completing the work.

Related:

Everything You Need to Know About Agile BPM in 2024

How to Draw?

The result looks something like this.

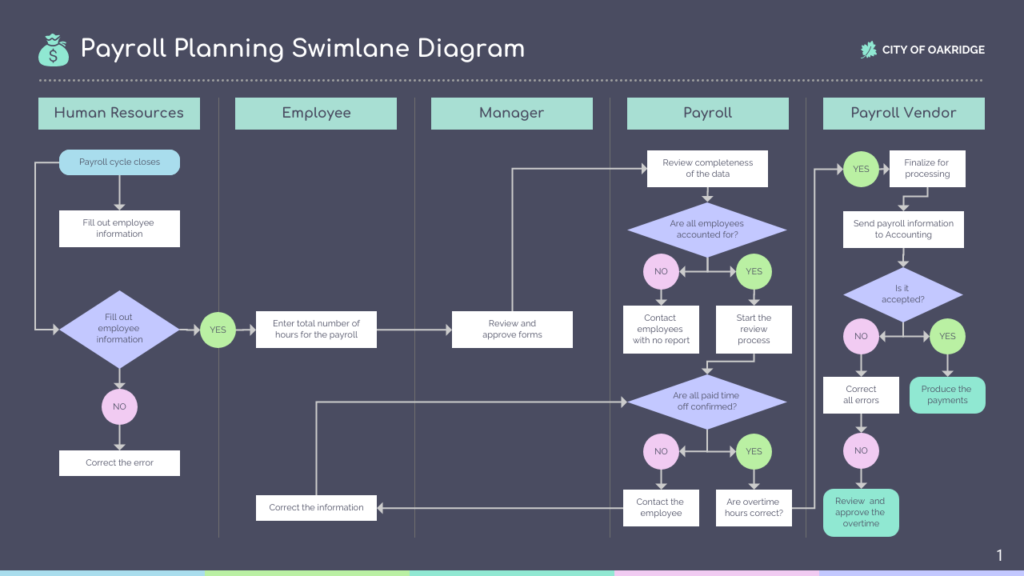

5. Swim-Lane Process Map

A swim lane process map can assist you in tracking work that is conveyed between teams or departments. Tasks, documents, data, and other items may be included. As the name implies, the chosen process is mapped from left to right and resembles pool swim lanes. Here’s when it should be used

When to Use

- To Delineate the specific individuals’ or departments’ responsibilities

- To Identify bottlenecks, redundancies, and extraneous steps to streamline processes

- To ensure that all necessary parties are included in a process

- To Create standardized work processes and document them in formats that can be easily shared

How to Draw?

This is how it works:

The various actors involved in the process are listed to the left. They catalyze the process. The result of a process is shown on the right.

The actual swim lanes are located in the center. Here’s an example of how to use a swim lane diagram to map a complex process

How to Construct a Process Map?

Now that you know what process mapping symbols are and what types of process maps exist? Here are the steps you must take to make an efficient process map

Step 1: Focus on The processes That Must Be Mapped

Determine where you want to begin. Is it the process itself that is failing? Is it the process that your new strategy is concerned with? Or is it the process that has a direct impact on customer satisfaction?

After that, give it a name.

Step 2: Create the Appropriate Team

Everyone involved in the process must contribute to ensure that when mapping it, every aspect of the process is covered. Those who do the work, manage the process, and provide feedback should all be on the right team.

Step 3: Compile All Required Data

- Where does the procedure begin and where does it cease?

- What are the steps between these two positions?

- What are the inputs and outputs of the process?

- Who is responsible for what? When, where, and how?

Step 4: Arrange the steps in a logical order

Request that your team arranges each step in sequential order from beginning to end.

Step 5: Create a Baseline Process Map.

Create a process map that depicts the map as it currently exists.

Step 6: Create and Track Improvements

Begin by implementing the changes on a smaller scale. If they prove to be more effective, they can be used on a larger scale. Examine the new and improved process to see how it is working and if it needs to be improved further.

Checklist for Process Mapping

- Begin by identifying the process’s start and end points before identifying the process steps. This helps to form limits.

- Make your process maps as easy to read and understand as possible for everyone in your organization.

- Only include the information that is necessary on your map. Not less nor more than what is required to identify areas for improvement

- Make certain that you follow the proper procedure. To avoid confusion, use map symbols when drawing.

- Include all key stakeholders in the process of mapping to avoid missing out on important information or steps.

- For efficiency, use business process mapping software that allows you to quickly draw and collaborate with your team in real-time.

A final word on process mapping

Process mapping is not only essential for process documentation; they are also a popular business process improvement methodology.

Follow the guide to create efficient business process maps and share any concerns you have, even if you use another process mapping technique.

More Resources: