The trends shaping the automotive industry will certainly impact its companies’ projects. What automotive industry challenges and issues will they bring to automotive project management, and what are the ways to address them? Read further to explore automotive industry problems and solutions in detail.

Challenges in Automotive Projects

The automotive industry is moving towards the new future by leaps and bounds. Its current development is primarily driven by 4 major trends: connectivity, autonomous vehicles, shared mobility, and electrification. All of them turn a car into a computer on the road, which requires installation of corresponding software and introduction of numerous features. This poses a number of challenges for the automotive companies: increasing competition, frequent changes as a result of rapid progress, establishing partnerships with software companies, and other related issues. Besides, there’s much uncertainty about supplying automotive manufacturers with necessary materials (e.g. global chip shortage), and the need for reducing production costs adds to the above-mentioned difficulties.

Now, let’s see how challenges in automotive industry will be reflected in the automotive companies’ projects.

Uncertainty

The ongoing pandemic, continuing global chip shortage and car manufacturers’ attempts to break their heavy dependence on tech suppliers, the application of innovative manufacturing technologies, device failure in newly manufactured cars, and other automotive issues are just a few examples of automotive industry problems. All these and other factors cause significant uncertainty and make it rather difficult to plan projects ahead. Besides, we shouldn’t forget about Murphy’s law – no project is immune to equipment failure, critical employees’ illnesses, extreme weather consequences, and other things that can go wrong. These aspects significantly affect automotive industry project management, and therefore, should be taken into account at all stages of the project lifecycle.

Increasing number of projects

As the automotive industry continues its development affected by recent unprecedented disruption, the number of projects its companies take on this year will be increasing. In addition, to stay competitive on the market, business owners will struggle to deliver their products faster and produce more (e.g. implement more advanced features than competitors). In addition, these projects are becoming more and more complex due to quickly developing technologies. As a result, automotive companies that used to have hundreds of projects underway are expected to be loaded with an increasing number of new complex initiatives running simultaneously. Such a complicated multi-project environment with its project dependencies and shared resources requires a well-thought project and resource management approach.

The need to cut costs

Industries and businesses still deal with the bits and pieces of the pandemic crisis, like global chip shortages or unforeseen massive production decline that happened in 2020. At the same time, recent trends in the automotive domain require serious investments into the vehicles being manufactured. This means that financial resources allocated for projects can be limited.

Talent deficiency

A lack of skilled resources is a common problem for most industries these days, especially those that deal with technology and manufacturing, and is one of the biggest problems in automotive industry. As stated by McKinsey, in the automotive industry, this challenge is explained by revolutionary changes in technology, business model, and consumer preferences. For example, innovations in automotive industry, the application of the latest manufacturing technologies (e.g. factory of the future) requires specialists with advanced technical skills, so it may be difficult to hire them as quickly as needed. Therefore, technology challenges in automotive industry are doubled by the lack of required talents. Besides, as automotive companies develop, grow and take on more and more projects, they need more people to work on them, but hiring new employees may take a long time and lead to significant increase of costs.

The need to shorten the product development time

To stay competitive on the market, automotive companies have to deliver their products faster. The vehicles have become a combination of software and hardware parts, and software development progress evolves much faster than hardware is manufactured. So, automakers have to change their approaches to product development to make it shorter but no less efficient, which, in turn, sets one more challenge for project management in automotive industry.

Globally distributed teams, equipment, and facilities

In today’s globalized world, companies can have their human and material resources located across the globe. It has certain benefits: they can reduce production costs due to placing industrial facilities in countries with cheaper workforce or vice versa – it becomes possible to bring together a team of high-end professionals regardless of their location. At the same time, managing large projects with globally distributed teams and material resources is rather challenging – they are miles away, but a project/resource manager has to keep track of all of them and make sure they are allocated to the right tasks. And if we talk about large organizations with hundreds of projects and thousands of globally distributed employees, this task becomes twice as difficult, which makes it one of the most critical challenges for automotive industry today.

Nevertheless, automotive companies need to deliver their projects as successfully and efficiently as possible. The tips below will help to achieve this goal by resolving problems in the automotive industry.

5 Tips on How to Address Project Challenges in the Automotive Industry

Prioritize projects and tasks

When the number of projects in a company is increasing, their prioritization is the key to cope with all of them successfully. First, when a new project comes in, it’s important for a project manager to analyze if it’s reasonable to start it right now or to postpone it, if there are enough available human and material resources to support all project management processes and ensure the successful delivery of products, and how it will affect the whole multi-project environment. Second, it’s important for a project leader to prioritize the tasks across the whole multi-project environment to know what should be managed first. Finally, prioritization makes it possible to fight bad multitasking and overload as the project team members know what tasks matter most at the moment.

Prepare for uncertainty and risks

One of the ways to cope with uncertainty in project management is establishing a time buffer: even if something goes wrong, there will be more probability that a project will be delivered on time.

Read more: Fighting Uncertainty in Project Management: Arm Yourself with the Right Tool

While uncertainty is impossible to manage, the same can’t be said about risks. Proper risk management will improve control over the project flow, provide better predictability of its outcomes, make it possible to detect any arising issues timely and predict or efficiently respond to them. Getting prepared for potential risks will increase the chance of smooth project delivery and minimize stress levels throughout the project lifecycle.

Read more: Project Risk Management: Importance, Challenging Issues, Recommendations

Utilize available resources with maximum efficiency

Here are some tips that help utilize your resources to the full and get the desired project outcomes.

- Plan resources’ capacity to determine if there’s a gap between required and available resources.

- Create cross-functional teams of employees who have a wide range of skills and can be interchangeable.

- Apply resource leveling technique: when available resources are limited, you can adjust a project’s timeline in accordance with the critical employee’s availability.

- Assign critical resources to the highest priority projects.

- Manage the employees’ workload – this will protect them from being overwhelmed and increase their efficiency.

Read more: How to Handle the Issue of Slow Recruitment with Resource Management Techniques

Adopt Agile project management process for product development

As car manufacturers have to quickly respond to customers’ growing demands and the automotive industry’s trends, the application of project management frameworks plays a crucial role in the whole delivery process. Agile approaches can be successfully used in automotive manufacturing because Agile is adaptive to changes and enables frequent value delivery in collaboration with customers. It can be used to decrease the vehicles’ time to market and manufacture products based on real users’ needs and taking their feedback into account. Therefore, it can ensure successful product development and achievement of business objectives.

Read more: Agile Product Development: Agile Methodology Explained

Use project/resource management software with advanced functionalities

Modern project and resource management software solutions provide numerous opportunities for automotive project management to create a project plan, organize work on a project in a maximum efficient way, take control of all projects in a multi-project environment, assist in efficient resource utilization, and as a result, plays a critical role in timely delivery, letting companies receive the desired project outcomes and increase customer satisfaction. Besides, some project management software solutions support predictive analytics capabilities and make it possible to detect potential risks and forecast bottlenecks, which contributes to smooth flow throughout the whole project lifecycle and successful project delivery. No matter how good project management skills you or your employees have, the adoption of project management software will significantly improve all the processes and project outcomes.

An example of such a software solution is Epicflow – a multi-project resource management tool that lets users improve all project management processes within a company and achieve project success with less stress. We’ll explore Epicflow’s features to illustrate their contribution to optimized project’s workflow.

Clear prioritization

Working in a multi-project environment, especially with engineering projects, it’s difficult to determine the right priorities among a great number of tasks and at the same time be mindful of every project’s limitations and dependencies between all of them. Epicflow is capable of automatic prioritization of tasks and projects across the whole multi-project environment, which significantly simplifies automotive project managers’ work. It takes into account the real-time data including all dependencies between projects to create a realistic project plan with accurately calculated priorities. As a result, both a project manager and every team member know exactly what tasks and projects they should work on at the moment. The list of prioritized tasks is available in Task List, while Pipeline allows you not only to monitor the state of the whole multi-project environment, but indicates what projects require most of your management effort showing your project status in real time.

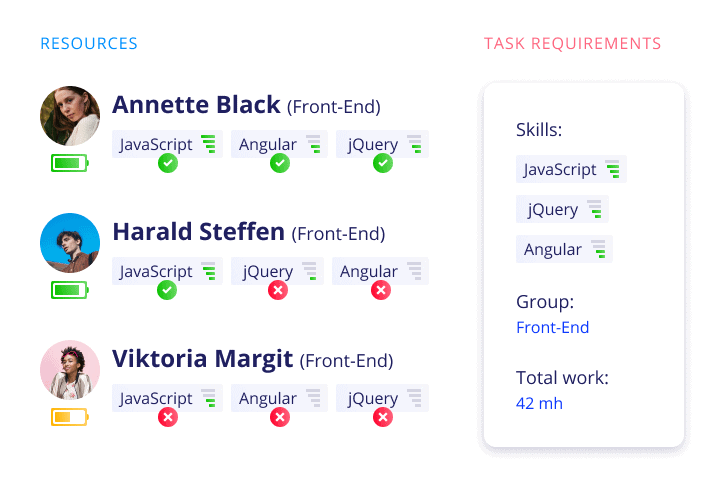

Informed resource allocation

To assign the right tasks to the right employees, you need to keep in mind each team member’s skills and capacity. But it’s an overwhelming task when there are hundreds or even thousands of employees working on numerous projects. Epicflow’s Competence Management feature keeps information on every employee’s skill sets and their capacity and what is more, uses this information to help automotive project managers assign a perfect employee for completing a certain task. Therefore, the resource allocation process becomes more efficient and simple no matter where your resources are located and how many people work on projects. Besides, as it monitors project performance from the perspective of resources, technical project managers are always sure they’re on the right track.

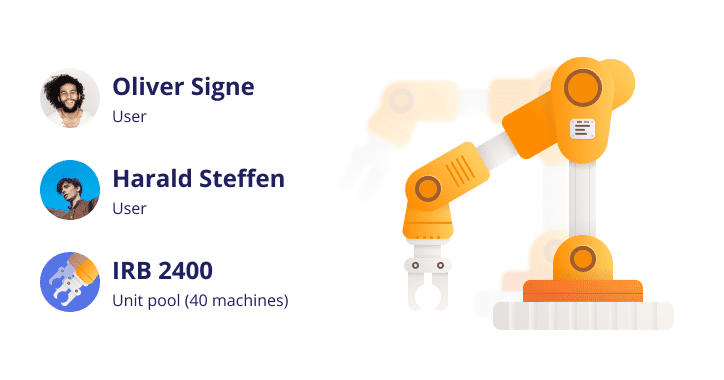

Managing material resources

When managing manufacturing projects, you have to control each project’s material resources – raw materials, equipment, tools, etc. Epicflow makes this task much more simple: in our system, you can create different types of resources and specify necessary information about them – price, hourly rate, measurement unit, and risk factor.

Also, you can collect all the necessary equipment used in a project into the Unit Pool. Similarly to assigning tasks to employees, you can assign them to equipment pieces. In addition, you can specify their availability and capacity as well as the number of their working hours per day and the number of machines in the calendar.

Therefore, in such a way, you’ll easily keep track of all material resources used for completing your complex projects, even if they are located in different corners of the world.

Making informed decisions

Decision making under conditions of uncertainty is really tough, so you’d probably want to know if you’ve made the right decision and what consequences it will have for a project’s further workflow. Epicflow gives a chance to test various scenarios and choose the most reasonable option based on a thorough assessment of risks. What-If Analysis makes it possible to predict outcomes of project environment changes based on the real-time information – you can see what will happen if you add or remove projects, move milestones, reassign resources, or make any other ad hoc decisions. The Future Load Graph shows your resources’ workload and the way it will change in the future so that you can analyze it and take necessary measures to keep it balanced.

Optimized work on similar projects

Working on multiple complex projects, you may have a number of typical project elements. You can save them in the Module Library and later use as templates for upcoming projects. It will certainly save your time and effort and make it possible to focus on more important work on a regular basis. For example, car manufacturing involves a series of repeated tasks performed by the same people or equipment. Instead of entering the same information for every new project, you can use templates from the Module Library.

Would you like to learn more about Epicflow and how to increase customer satisfaction by addressing challenges facing the automotive industry? Book a demo with our specialists to learn how Epicflow project management software supports project managers at automobile companies and explore more of its advanced capabilities for your perfectly streamlined project orchestration and desired project outcomes. Reach your project goals faster with Epicflow!